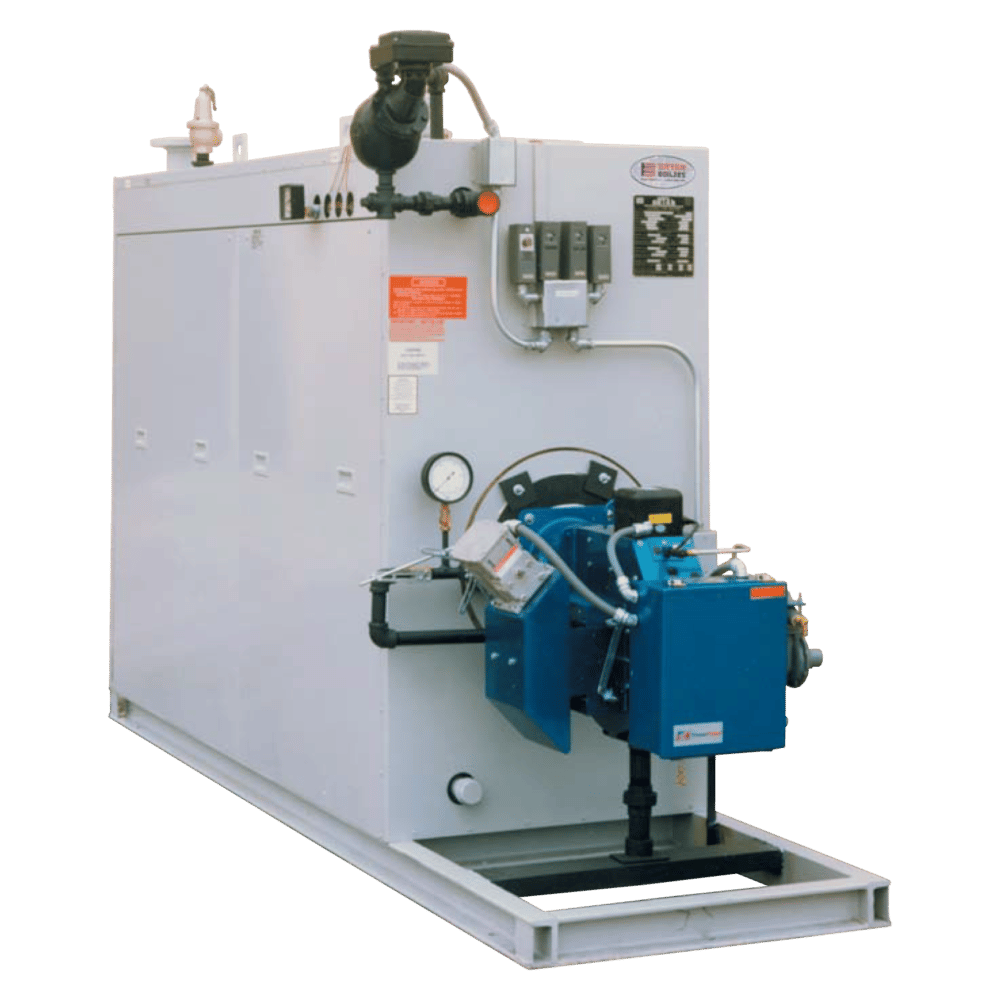

Product Details

Size Range

250,000 - 850,000 BTU/HRFuel Options:

Natural Gas, Dual Fuel, Propane, #2 Fuel OilBryan Steam offers forced draft boilers dual fuel boilers and oil hot water and steam boilers. High efficiency boilers of the forced draft series are available as well, offering guaranteed performance to 85% without complications of condensation.

Guaranteed efficiency

The breakthrough in water tube boiler design that produced the DR Series provides operating efficiency so reliable, we guarantee it to be 83.5% for hot water boilers and 82.5% (15 psi) or 80% (150 psi) or better for steam boilers.

The Bryan DR series boiler is a true flexible water tube design with pressurized firing for high efficiency. Large volume water leg downcomers promote rapid internal circulation, temperature equalization and efficient heat transfer.

The Boiler tube and furnace area access panel is constructed of heavy gauge steel, lined with high temperature ceramic fiber and insulation. With single side access; combustion chamber, tubes and burner head are completely accessible from one side, simplifying maintenance and minimizing floor space. Multiple burner options are available; forced draft, flame retention head type burner. The DR series boiler provides efficient combustion of oil or gas, providing quiet operation.

Guaranteed boiler design that produced the DR Series provides operating efficiency so reliable, we guarantee it to be 83.5% efficiency The breakthrough in water tube for hot water boilers and 82.5% (15 psi) or 80% (150 psi) or better for steam boilers.

he Bryan Flexible Tube Bryan’s exclusive “Flexible Tube” design eliminates the possibility of damage from so-called “thermal shock.” Tubes are easily removable and replaceable, without welding or rolling, eliminating long, expensive downtime should repairs ever be required.

Water cooled furnace The configuration of the water tubes provides a water cooled combustion chamber. A high percentage of the heating surface is exposed to direct radiant heat, increasing water velocities and heat transfer.

Compact design, minimum floor space With our compact water tube design, the overall size of the unit is less than most other types of boilers. Needing only 24″ for tube removal, and on only one side of the boiler, the DR Series boiler occupies very little space in the boiler room. This can result in considerable savings in building costs.

Pressurized firing permits minimum sized breaching and vent. Multi-pass flue gas travel High velocity four-pass flue gas travel is obtained by a unique baffling system. This contributes to maximum fire side heat transfer and overall high boiler efficiencies.

Thermal blend water return

Bryan’s unique “thermal blend” return blends cold or cooler return water with warmer boiler water abridging it to design operating temperatures. An injector tube directs the “mixed” water flow through the downcomer to the lower header and heating surfaces at a temperature above possible condensing conditions. This reduces the possibility of “cold spots” and damage from corrosive condensation. Positive internal circulation Each pass of the Bryan water tube slopes upward. This configuration, along with the large volume down-comer water legs, provides the extremely rapid natural thermal internal circulation, promoting both high efficiency of heat transfer and uniform temperature throughout the boiler.

Eliminating stress damage caused by unequal temperature distribution is especially important for heating systems, particularly where intermittent or continuous low temperature water returns may be encountered.

Learn more

Please contact our team for more information on this product.